The hexagonal mesh between the fan blades and the test section, this helps remove the rotational movement of the air.

This was earlt testing of the affect of wind of the water atomiser, which is the device that creates the mist seen in the tunnel.

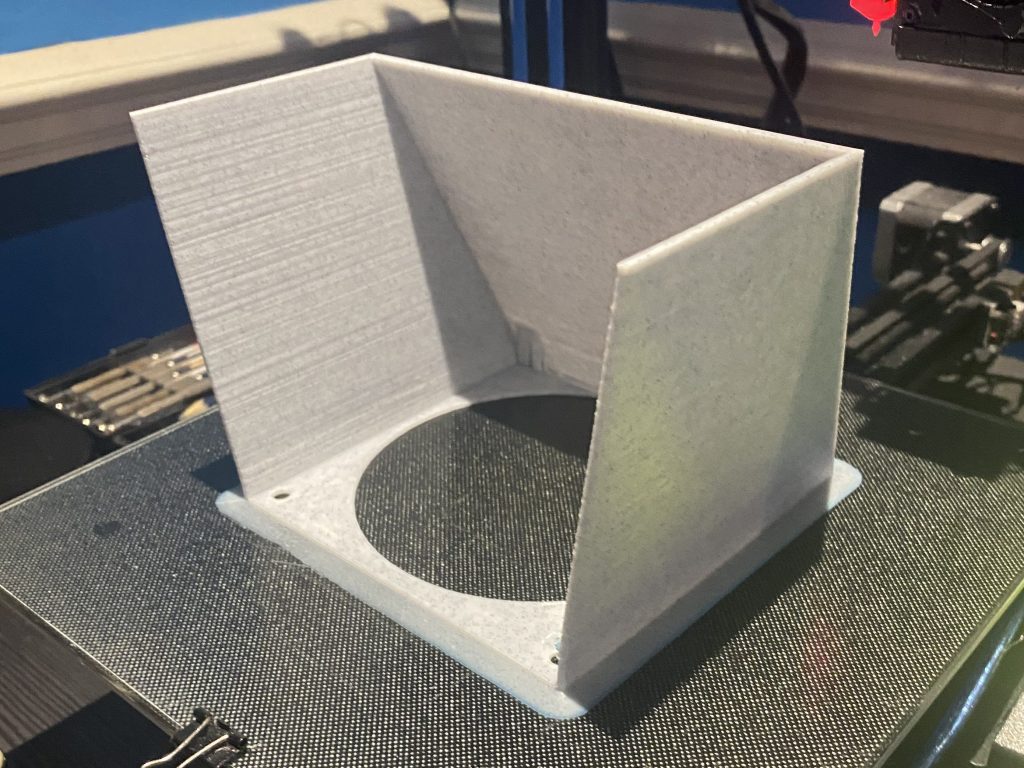

one of the two halves of the diffuser after it had finished being 3d printed, this half took 10 hours to complete.

one of two 120mm fans that provides the wind in the wind tunnel. this fan moves 5000 liters of air a minute.

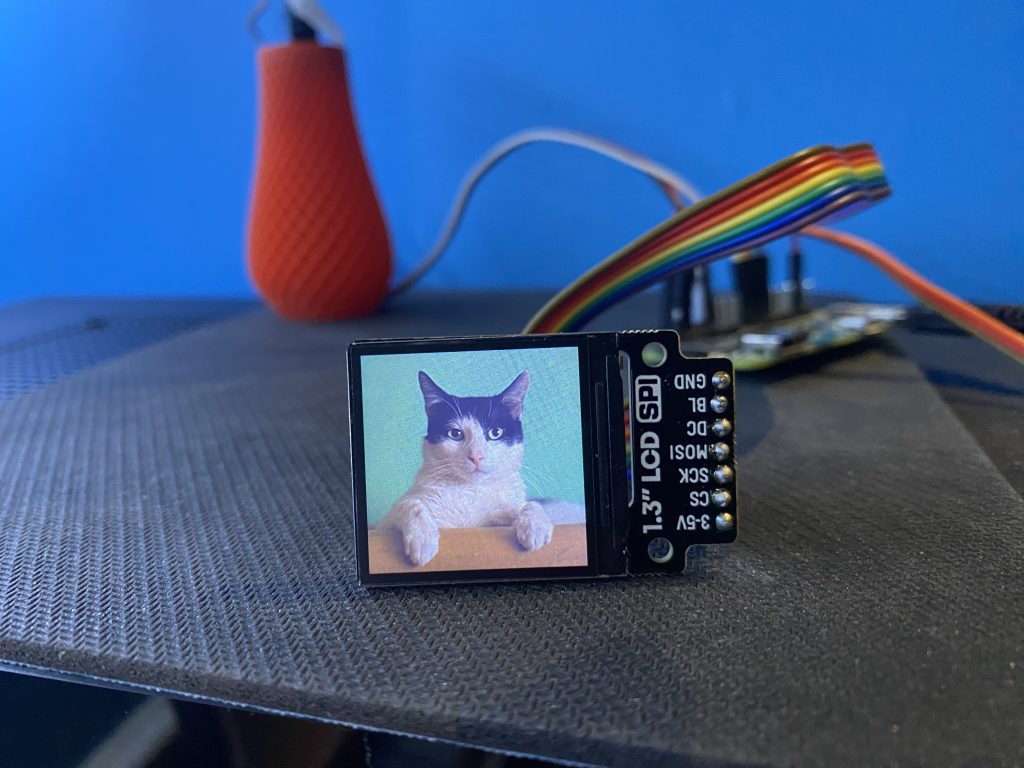

everywhere good on the internet has a cat, here is one on the display that we used.

part of the tunnel during the woodwork stage of construction.

testing the effects of suction through a funnel on the mist.

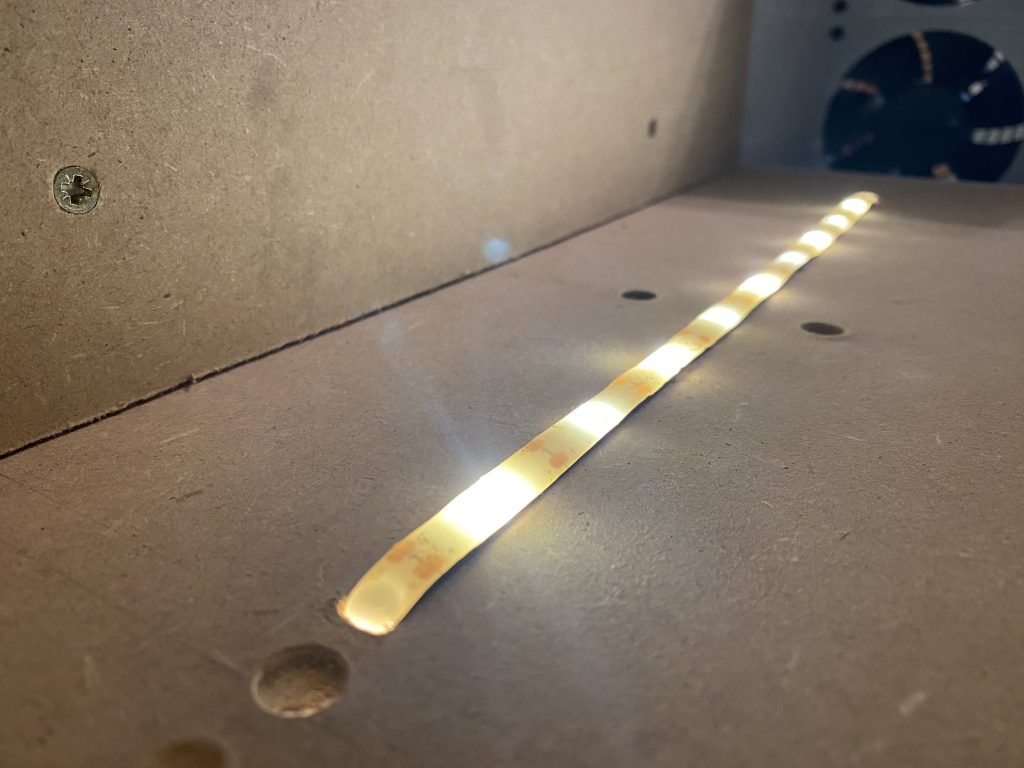

partway through construction, focusing on adding the internal lighting for the tunnel.